by Thomas Degen

Looking back the past decade, the term Industry 4.0 (I4.0) has been introduced to the world originating as “Industrie 4.0” by a German governmental lead high-tech strategic initiative in 2011. Since then more and more industry experts, technologists, manufacturing practitioners and suppliers have been discussing how to support the factories’ shopfloors with better administration and control, higher overall equipment effectiveness (OEE), more automation, improved safety and security just to name a few by smarter digital solutions.

Eventually in a steel factory the blast furnace controller has been replaced with a Windows based system. Or the machinists operating the production facilities at a manufacturer’s shopfloor have been equipped with tablets attached to the walls displaying a graphical representation of current production cycles in stylish dashboards embedded into the Operation Technology (OT) systems. But is this really Smart Manufacturing?

After an initial inspection, I mostly tend to answer with “No” surprising factory management and I4.0 Chief Digital Officers. Systems might have been modernized somehow with more known operating systems and have been adapted from analogous world with digital connections for better monitoring and control through a Manufacturing Execution Systems (MES). And other new challenges have appeared for OT with these new technologies. The move of the steel factory’s blast furnace controller to a Windows based system has made this controller the most neuralgic vulnerable point of failure in the whole steel factory overnight. Once a careless sloppy service technician has attached for a Windows operating system update his with a virus contaminated USB-stick to the Windows server causing production still-stand for one day until the server has been finally restored from backup.

Production of the factory has still been impacted the rest of the week. You do not switch on steel production like electric light, steel production has to settle down into the optimal control cycles for high quality steel grade to get produced as ordered by the client. The Windows server at the steel factory finally has become sealed within a cage grid that only authenticated and authorized staff are allowed to enter.

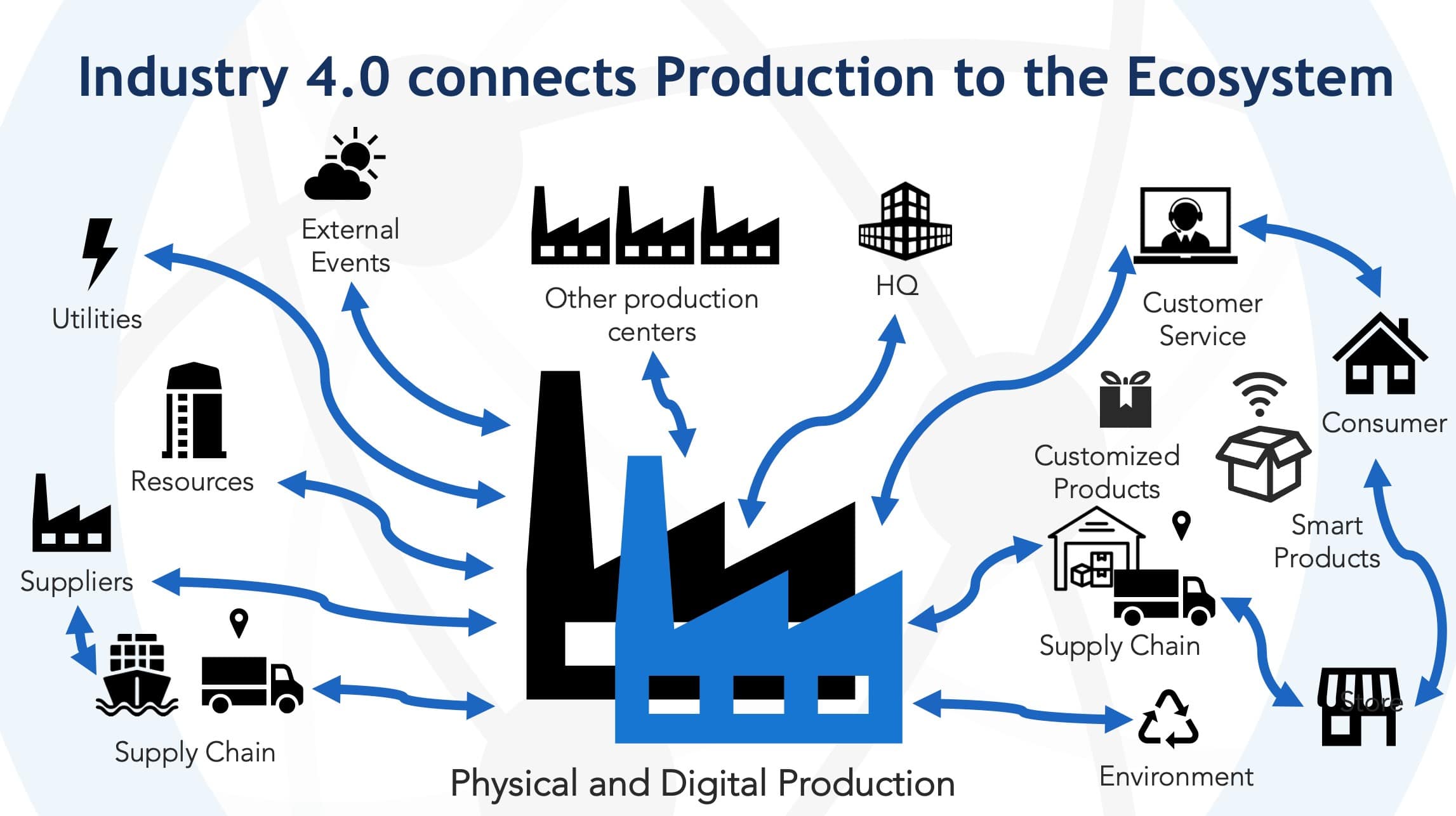

Smart Manufacturing or I4.0 is actually envisioning Operational Technology (OT) shopfloor systems being connected with the Enterprise’s Information Technology (IT) world. Industry 4.0 implies that foreground physical production is supposed to be shadowed by digital production linking the results, incidents and output from the shopfloors with the Enterprise ecosystem like supply chain, suppliers, partners and of course with the customers down the whole value add cycle. Factory OT systems from the shopfloors are supposed to get combined together with the Enterprise IT from topfloors like ERP, CRM and legacy systems. Together with supplier and partner solutions the smart production is powered by artificial intelligence algorithms & machine learning models for anomaly fault detection or better more efficient anticipating maintenance.

This architecture of physical and digital production is referred to as Digital Twin.

So what are the barriers looking back the last ten years that smart manufacturing powered by Artifical Intelligence has not started through yet?

Three major obstacles have been around: Organization, Infrastructure and Solutions. Let me elaborate on each of these items some bits.

Organization – Traditionally shopfloor OT production and Enterprise IT topfloor systems have been run by different teams naturally creating a gap between their solutions. This principle is known as Conway’s law. Computer scientist Melvin Conway has observed during the 60ies that organizations build systems that are reflecting the organization’s internal communication lines. Where social communication is hard or difficult, the little too less open are the system’s interfaces and interactions between the solutions of the internal groups and teams in the organization. This is why there is so much emphasis about OT and IT convergence. It is one goal of Industry 4.0 to break the ice between these traditionally separated disciplines within the organization.

Infrastructure – Production plants have not necessarily been equipped with sufficient network capacity. Neither LAN nor WLAN is available to transfer XX Gigabytes per minutes summing up to XX Terabytes per day into a big-datamart for decent data mining and ML model validation, training and optimization. So to say that not every equipment especially from the old century is digital connectable, Open APIs are little too low existent. If equipments have file connectors exchange capabilities, this is a good starting point for an integration exercise, there might be more modern type of integration hooks existent. Still various kind of proprietary protocols, APIs and SDKs with different metamodels leave it with the system integrator to normalize the data into a common format for use upstream the system’s chain.

Solutions – The massive data that is getting produced from equipment on the shopfloor couldn’t get followed up with analytical solutions combining real-time with intraday and historian data. Lack of semantics in the data feeds from different types of equipment has added additional complexity for the solutions to cope with the high volume and variety.

Today the three main barriers mentioned above have been overcome. System Integrators (SI) have identified edge integration and edge anomaly detection for equipment integration as new value added services expanding for their service management catalogs. ITSM services for fabrique LAN, fabrique WLAN, network, computing and storage are updated with OTSM items for equipment integration and monitoring.

As the System Integrators are covering full end-to-end responsibility agreed via service level agreements (SLAs) with the endusers, the traditional organizational OT/IT gap is getting bridged by them. With such a gap still existent, the SIs cannot guarantee their offered SLA and wouldn’t bring better efficiency and optimized operations to their new industrial clients. In the infrastructure area the new 5G cellular network standard brings by the telecommunication operators the capability to deploy Multi Access Edge Compute (MEC) nodes. These MECs are including networking infrastructure, cellular connectivity across local private industrial cellsites with multi Gbit/s bandwidth and portable datacenters for local real-time pre-processing of collected data from the equipments. The formerly disconnected plant site is fully attached to the Enterprise’s central IT. Last but not least the solutions are finally capable to handle the new massive parallel data-intensive sensor data and feeds from legacy systems and new technologies. AI algorithms and ML models borne in the System Integrator’s and/or Enterprise’s large big datamarts are eventually containing hundred years of operational experience. These models can get in time optimized, re-trained, by re-simulations validated and through ad-hoc and automated deployments updated for execution on the edge close to the equipments at the shopfloors. Use cases behind these efforts are anomaly and fault detections, predictive and preventive maintenance and the remote command and control room. Nearshore and offshore operations of production sites from a central managed service center allow for remote monitoring, administration, control and command.

This is now the decade AI for Smart Manufacturing, the sixth Kondratiev wave has arrived at the shopfloors !